Originally appeared in Sept 2013 Newsletter.

Written by K. Myers

It may be surprising to some that originally Cottage Grove was a gold town. In many ways Cottage Grove continued to be a gold town long after mining slowed down. Green gold, timber, to be exact. Logging and mills replace metal gold with the green trees of Oregon.

It may be surprising to some that originally Cottage Grove was a gold town. In many ways Cottage Grove continued to be a gold town long after mining slowed down. Green gold, timber, to be exact. Logging and mills replace metal gold with the green trees of Oregon.

One article could never cover the rich history of logging in the Cottage Grove area. In one book alone there are over 110 mills identified that existed in or around Cottage Grove. (Green Gold by O.J. Theil, available for review at the Cottage Grove Historical Society Research Library.) Instead, we will follow the journey of one mill from the J.I. Jones sawmill to Booth-Kelly, and eventually Weyerhaeuser.

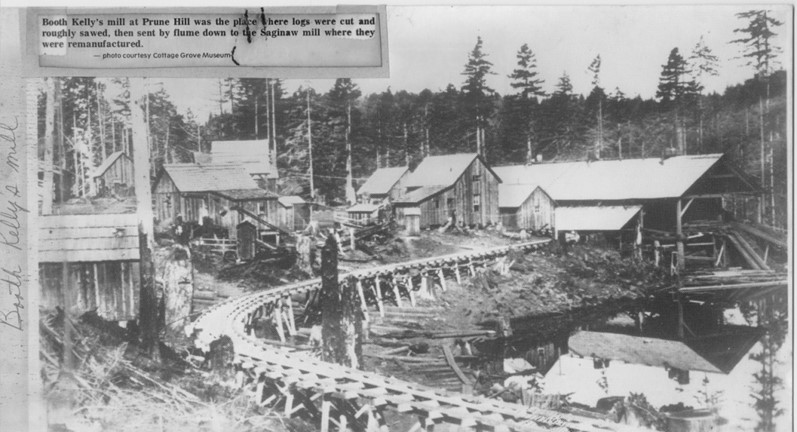

The first sawmill in the Cottage Grove area was built west of Silk Creek in 1857 by Mr. Harvey Hazelton. A few years earlier settlers in Dorena had put together a “sort of sawmill around 1853 to provide lumber for their homes” (Golden Was the Past pg 180). It was not until approximately 1895 that J.I. Jones built the J.I. Jones sawmill near Saginaw. According to Green Gold, J.I. Jones also owned a mill in Disston. Jones’ Saginaw mill was one of the largest in the area and included a six-mile flume to move timber.

In 1898, Robert A. Booth and brothers George and Tom Kelly joined forces to create the Booth-Kelly Lumber Company and purchased J.I. Jones Mill in Saginaw. According to various sources, the price was between 70,000 and 500,000 dollars, at the time Jones was only 32 years old. Golden Was the Past states the sale price at “$70,000 in 1898” (p.181).

By 1899 the sawmill was running on electricity. This meant that the sawmill didn’t have to stop production during winter, allowing year-long production. 1899 was a big year for the Booth-Kelly operation, they bought a mill in Coburg, and also began to buy tracts of timber at a larger scale than ever before. The company also built a third mill in 1899. By May 4th of 1899, the company’s stock was 1,000,000 dollars.

Booth-Kelly continued to expand, by 1911 the capital had been increased to 2,500,000 dollars and by 1922 the operation was employing the most employees it ever had or would, 825 men were on the payroll.

Booth-Kelly continued to expand, by 1911 the capital had been increased to 2,500,000 dollars and by 1922 the operation was employing the most employees it ever had or would, 825 men were on the payroll.

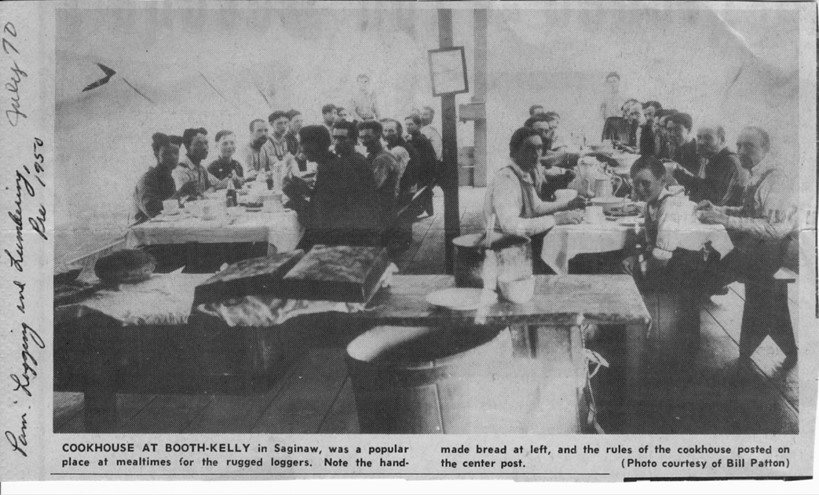

A typical work week in the late 19th and early 20th century included a 10-12 hour day, 6 days a week. The pay was around a dollar a day. Men lived in bunkhouses until around the 1900’s. Dormitories were built around that time, with 2 men to a room. Living conditions improved quite a bit in the first years of the 20th century. One big improvement saw men and their families living in the logging camps provided with small cabins. These camps would often have their own small store, school, and church services. A 1905 diary from a logger’s wife, Flora Hills, read “Had a big venison feed. Fried venison, boiled potatoes and gravy. Loggers will eat anything if it has enough gravy on it.”

Through the years the logging industry has had ups and downs right along with the rest of the economy. Technology brought progress and the passage of time saw changes in ownership. In 1958, Georgia Pacific bought out the Booth-Kelly operation of Cottage Grove, Oregon.

Later on, around 1985, Weyerhaeuser bought out Georgia Pacific. Cottage Grove’s history can be divided into four main eras, the Native American time period, the gold rush, the timber era, and now as a highway town. Green gold is still a large part of many people’s lives, and will very likely continue to be such for a long time.

Getting Timber to the Mill

By Holli Turpin

Over the years there have been several processes used to transport timber from the mountains to the mills. Some earlier, smaller mills simply set up in the area they were logging. Steam Donkeys made turning timber into lumber a portable process. When mills became large operations, transporting timber became a necessity.

Water - Timber was drug to rivers and floated downstream to a mill.

Horse or oxen teams - Used to drag timber to landings or pull wagons of timber to the mill.

Train - While it was still necessary to get the timber from the hillside to the train, trains were an effective way to get timber to the mill.

Flumes - Used waterpower and gravity to get logs to the mill. They were also used to get loggers home at the end of the week. Water from the flume provided cool, fast transportation, that might have provided a much needed wash before heading getting home with the weekly paycheck, but one would imagine the ride was rough.

Log Truck – most widely used method since its inception. Trucks have changed over the years from rough riding steel wheels and bench board seats to rubber tired, air cushioned shocks and padded bucket seats.

Hot Air Balloon - Short lived, but memorable, often regailed in stories from hunters who came across mysterious floating objects as they crested ridges in the early morning fog. This method of moving logs was featured in the Disney movie "Chester, Yesterdays Horse" filmed in the area in 1973.

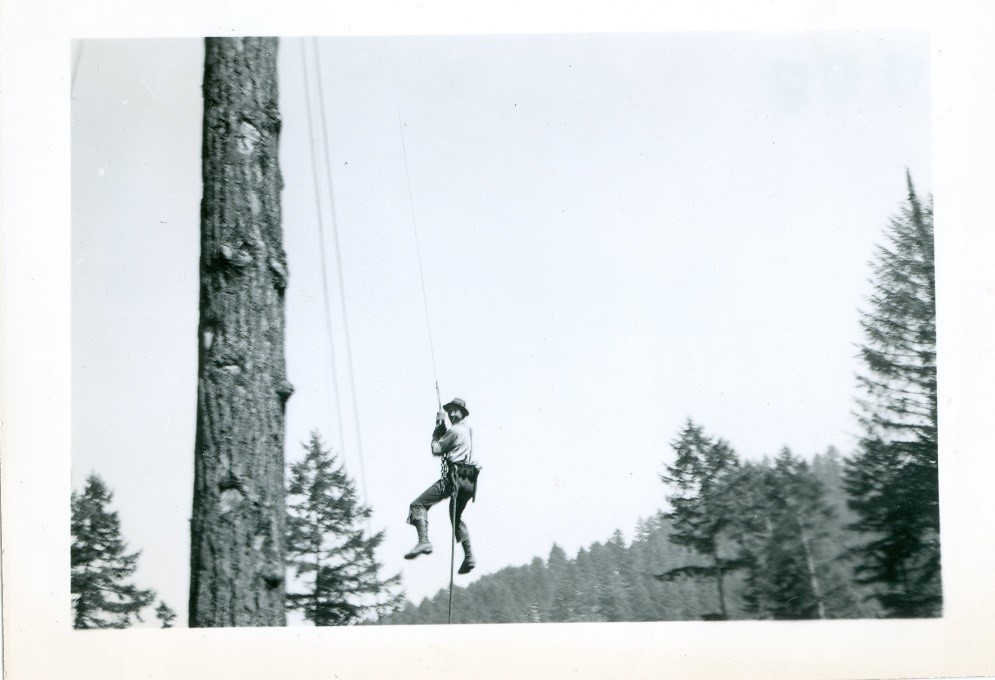

Helicopter - logs are transported from logged hills to a nearby landing by helicopter, then moved to the mill via log truck. This costly method is usually employed in especially challenging terrain.

Across time the need remains the same, get logs from mountain to mills. You can still find logs being pulled by horses, floated on waterways, carried by trucks and flown by helicopter. We may miss the flumes but one has to assume that the log rides at amusement parks around the globe are remnants of logging history.